Effective inventory management is the lifeblood of a healthy business, separating thriving enterprises from those struggling with tied-up capital and dissatisfied customers. It's far more than just counting stock; it's a strategic discipline that directly impacts your cash flow, operational efficiency, and ability to meet market demands. A reactive approach often leads to costly mistakes, either through overstocking that drains resources or stockouts that damage customer loyalty and brand reputation.

Mastering this discipline requires moving beyond foundational knowledge. For a comprehensive understanding of the core concepts, you might find this guide on What Is Inventory Management: A Founder's Guide particularly useful. This article, however, moves beyond the basics to provide a curated roundup of nine powerful inventory management best practices. Each strategy is a proven method for gaining control, improving visibility, and turning your stock into a genuine competitive advantage.

We will explore actionable techniques ranging from ABC analysis for prioritising high-value items to Just-in-Time (JIT) systems that minimise holding costs. You'll learn how to calculate your Economic Order Quantity (EOQ), implement precise demand forecasting, and maintain accuracy through cycle counting. This guide is designed to be a practical toolkit, offering specific implementation steps for each practice. By applying these methodologies, you can transform your supply chain from a reactive cost centre into a streamlined, profit-driving machine, fully organised to support your business growth.

1. ABC Analysis for Inventory Prioritisation

Not all inventory is created equal, and treating it as such is a common operational pitfall. One of the most effective inventory management best practices is implementing ABC analysis, a categorisation technique that segments stock based on its value to your business. This method applies the Pareto Principle (often called the 80/20 rule) to inventory, helping you focus your resources where they matter most.

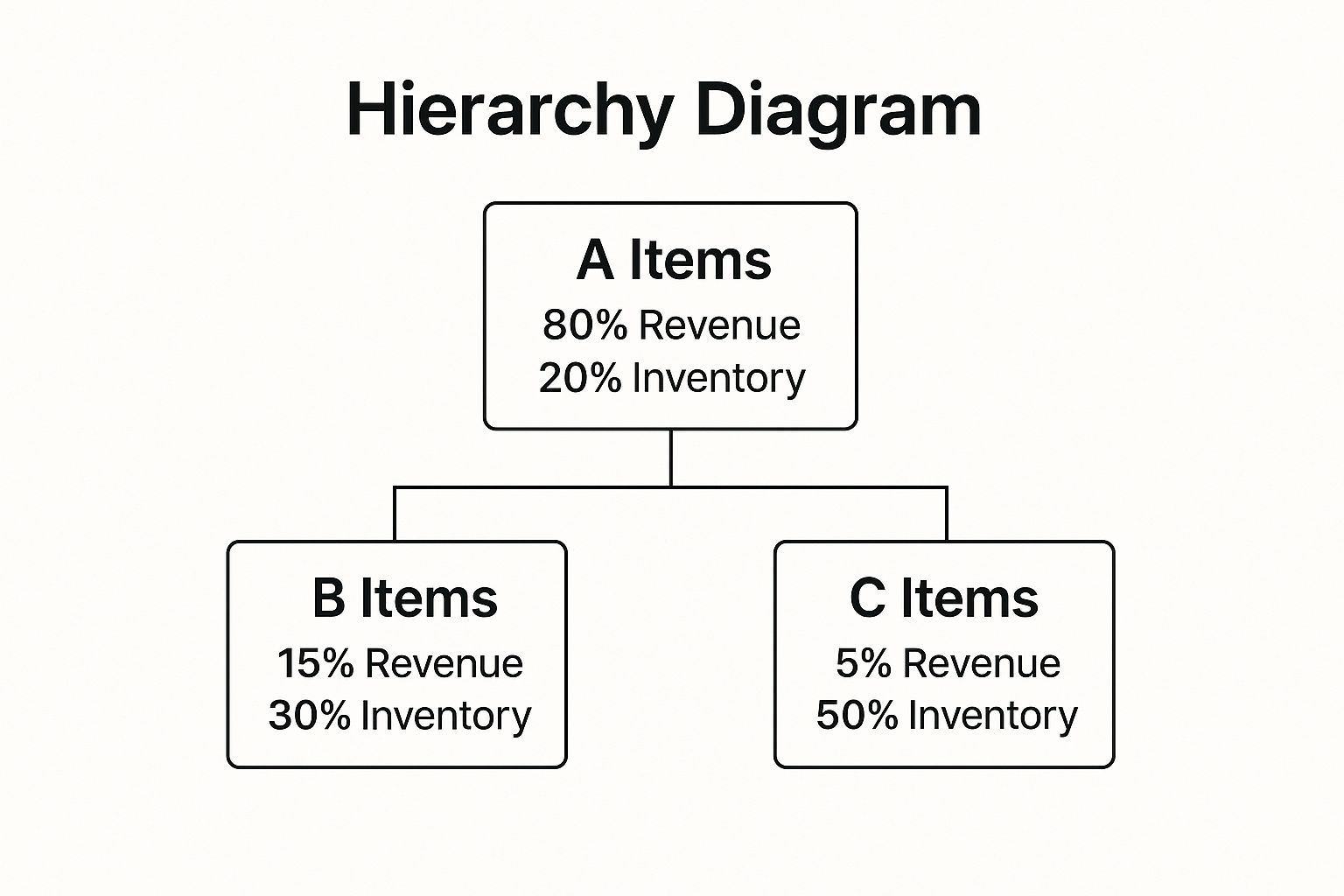

The core principle involves dividing your inventory into three distinct categories:

- A Items: These are your most valuable products, typically representing a small portion of your total inventory (around 20%) but contributing the majority of your revenue (about 80%).

- B Items: This middle category consists of products with moderate value. They make up a larger portion of your stock (around 30%) and contribute a smaller percentage of revenue (about 15%).

- C Items: These are the low-value items that constitute the bulk of your inventory quantity (around 50%) but only generate a small fraction of your total revenue (about 5%).

By organising your stock this way, you can tailor your management strategies. For example, high-value 'A' items warrant tight control, frequent cycle counts, and sophisticated demand forecasting to avoid costly stockouts. In contrast, 'C' items can be managed with simpler, automated reordering systems, freeing up valuable time and capital.

How to Implement ABC Analysis

- Calculate Item Value: Multiply the annual number of units sold for each item by its unit cost to determine its annual consumption value.

- Rank and Categorise: Rank all items from highest to lowest based on their annual consumption value. Then, apply the 80/15/5 percentage splits to classify them into A, B, and C categories.

- Apply Differentiated Controls: Develop specific inventory policies for each category. 'A' items might require weekly reviews and just-in-time delivery, while 'C' items could be reviewed quarterly with higher safety stock levels.

The following infographic illustrates the typical hierarchical relationship between these inventory categories and their contribution to overall revenue.

This visualisation clearly shows that a small fraction of inventory, the 'A' items, is responsible for the vast majority of revenue, highlighting why it deserves the most management attention. Global retailers like Walmart and Amazon use sophisticated ABC analysis to optimise stock levels in their distribution centres and stores, ensuring high-demand products are always available while minimising holding costs for slower-moving items.

2. Just-in-Time (JIT) Inventory Management

Holding excess stock is a direct drain on capital, tying up funds that could be better used elsewhere. Just-in-Time (JIT) inventory management is a lean strategy designed to combat this inefficiency by aligning stock orders from suppliers directly with production schedules or customer demand. The goal is to receive goods only as they are needed, drastically reducing inventory holding costs and minimising waste from overproduction or obsolescence.

This method, popularised by Toyota's production system, transforms a business's supply chain from a "just-in-case" model to a highly efficient, responsive "just-in-time" operation. Success hinges on precise demand forecasting and exceptionally reliable supplier relationships, as there is little room for error. A delay in one part of the chain can halt the entire production process. To effectively implement this model, some companies explore how modern manufacturing offers benefits of 3D printing for on-demand production of replacement parts, further reducing the need to hold physical stock.

How to Implement JIT Inventory Management

- Develop Strong Supplier Partnerships: Forge close relationships with a small number of reliable suppliers. Long-term contracts, clear communication channels, and proximity can help ensure on-time deliveries.

- Invest in Accurate Forecasting: Use powerful inventory management software and data analytics to predict demand with high accuracy. This is the foundation upon which the entire JIT system rests.

- Implement a Kanban System: Use visual signals (Kanban cards or digital alerts) to trigger the movement of materials within your production line or supply chain. This ensures components are only requested when a need arises.

- Start with a Pilot Programme: Before a full-scale rollout, test JIT with a specific product line or a single supplier. This allows you to identify and resolve potential issues on a smaller, more manageable scale.

Many leading companies have mastered JIT. Dell revolutionised computer manufacturing by building machines to order, while fast-fashion giant Zara uses JIT principles to rapidly move new designs from the catwalk to its stores, responding almost instantly to emerging trends. These examples demonstrate the power of JIT as one of the most effective inventory management best practices for reducing waste and boosting agility.

3. Economic Order Quantity (EOQ) Optimisation

Balancing the costs of ordering new stock against the costs of holding it is a fundamental challenge in inventory management. One of the most powerful inventory management best practices for tackling this is using the Economic Order Quantity (EOQ) formula. This time-tested calculation helps businesses determine the ideal quantity of inventory to order with each purchase, minimising the combined expenses of ordering and carrying stock.

The goal of EOQ is to find the perfect equilibrium. Ordering too frequently in small batches leads to high ordering costs (staff time, shipping fees), while ordering large quantities infrequently inflates carrying costs (storage space, insurance, obsolescence).

This formula identifies the order size that keeps your total inventory costs at their lowest possible point. The core variables in the standard EOQ formula are:

- Annual Demand: The total number of units you sell in a year.

- Order Cost: The fixed cost incurred each time you place an order (e.g., administrative fees, shipping).

- Carrying Cost: The cost to hold one unit of inventory for a year, expressed as a percentage of the unit cost.

How to Implement EOQ

- Gather Your Data: Collect accurate figures for annual demand, the cost per order, and the carrying cost per unit. This is the most critical step, as the formula's accuracy depends on reliable inputs.

- Calculate EOQ: Apply the standard formula: EOQ = √ (2 * Annual Demand * Order Cost / Carrying Cost). This will give you the optimal number of units to include in each order.

- Adjust and Apply: Use the calculated EOQ as a baseline. You may need to adjust it based on practical constraints like supplier minimums, storage capacity, or potential quantity discounts.

By using EOQ, you can create a more predictable and cost-effective reordering process. For example, consumer goods giants like Procter & Gamble apply EOQ principles to manage raw material purchasing, ensuring a steady supply for production without overstocking. Similarly, grocery chains use it for non-perishable goods, optimising shelf space and reducing capital tied up in slow-moving stock.

4. Demand Forecasting and Planning

Operating without a clear view of future sales is like navigating without a map. One of the most critical inventory management best practices is demand forecasting, the process of predicting future customer demand using historical sales data, market trends, and statistical modelling. Accurate forecasting is the foundation of efficient inventory control, enabling businesses to avoid the dual costly mistakes of stockouts and overstocking.

The core principle is to move from a reactive to a proactive inventory strategy. Instead of just reordering when stock is low, you anticipate future needs, allowing for better resource allocation and smoother operations. This process involves analysing several data streams:

- Historical Sales Data: Reviewing past sales patterns to identify trends, seasonality, and cycles.

- Market Conditions: Considering external factors like economic shifts, competitor activities, and industry trends.

- Promotional Activities: Factoring in the projected impact of upcoming marketing campaigns, sales, and discounts.

- Qualitative Insights: Incorporating feedback from sales and marketing teams about new opportunities or potential market changes.

By combining these elements, you create a data-driven projection of what customers will buy and when. This allows you to align your purchasing and production schedules precisely with anticipated demand, optimising stock levels and improving cash flow.

How to Implement Demand Forecasting

- Gather and Clean Data: Collect at least two years of historical sales data. Ensure the data is clean by removing anomalies or accounting for one-off events (like a bulk clearance sale) that could skew the forecast.

- Choose a Forecasting Method: Start with simple methods like moving averages or seasonal indexing. As you grow, you can explore more sophisticated statistical models or even machine learning algorithms for greater accuracy.

- Collaborate and Refine: Involve sales, marketing, and finance departments in the forecasting process. Their insights can add crucial context that raw data might miss. Regularly review and adjust your models based on their performance.

- Measure and Improve: Use metrics like Mean Absolute Deviation (MAD) or Forecast Accuracy to track how close your predictions are to actual sales. Continuously use this feedback to refine your methods over time.

This proactive approach is essential for maintaining a competitive edge. Global sportswear giant Nike, for instance, uses advanced analytics to forecast demand for seasonal equipment, ensuring products hit the shelves just as consumer interest peaks. Similarly, Coca-Cola employs machine learning to predict regional beverage demand, optimising its complex global supply chain.

5. Real-time Inventory Tracking and Visibility

Relying on outdated spreadsheets or periodic manual counts is a recipe for stockouts and overstocking. One of the most transformative inventory management best practices is the adoption of real-time tracking, which provides continuous, up-to-the-minute visibility into stock levels, locations, and movements. This practice leverages technologies like barcodes, IoT sensors, and cloud-based systems to ensure information is always accurate and current.

The core principle is to create a digital twin of your physical inventory, where every scan, movement, or sale is instantly recorded in a central system. This eliminates guesswork and provides a single source of truth across all channels, from the warehouse floor to the e-commerce storefront.

- Accurate Data: Manual data entry is prone to human error. Automation minimises these mistakes, leading to more reliable inventory records.

- Improved Efficiency: Staff can locate items faster, order fulfilment is streamlined, and receiving processes are accelerated, boosting operational productivity.

- Enhanced Customer Experience: Accurate stock information prevents overselling and allows for precise delivery estimates, increasing customer satisfaction.

By establishing this live view of your inventory, you empower your team to make faster, more informed decisions. Global logistics giant FedEx uses real-time tracking to manage millions of packages daily, while Zara tracks its fast-fashion items across over 2,000 stores, enabling rapid replenishment and response to sales trends.

How to Implement Real-time Tracking

- Select Appropriate Technology: Choose the right tools for your operation. Barcode scanners are a great starting point for many businesses. For comprehensive real-time visibility, advanced technologies are crucial. You can learn more about RFID labels for inventory and asset tracking for a more automated approach.

- Integrate Your Systems: Ensure your tracking technology integrates seamlessly with your central management platform, such as an Enterprise Resource Planning (ERP) system. The benefits of integrating these systems are significant for achieving a unified operational view.

- Train and Audit: Thoroughly train all staff on using the new hardware and software. Schedule regular audits where you compare system data against physical counts to verify and maintain accuracy.

Implementing real-time visibility is a key pillar of modern inventory management best practices. It turns inventory from a static liability into a dynamic, transparent asset that can be managed with precision and confidence.

6. Safety Stock Optimisation

Uncertainty in demand and supply is a constant challenge in inventory management. Safety stock optimisation is the practice of holding an additional quantity of an item in inventory to reduce the risk of stockouts caused by these fluctuations. It acts as a strategic buffer, ensuring you can meet customer demand even when forecasts are inaccurate or supplier deliveries are delayed.

The goal is to find the perfect equilibrium between providing excellent customer service and minimising the capital tied up in excess stock. Too little safety stock leads to lost sales and dissatisfied customers, while too much results in high holding costs, obsolescence risk, and wasted warehouse space. This makes calculating the right amount a crucial element of any robust inventory management best practices.

- Demand Variability: Sudden, unexpected increases in customer orders.

- Supply Variability: Delays in supplier shipments or receiving fewer items than ordered.

- Lead Time Fluctuations: The time it takes for an order to arrive varies.

By systematically calculating and maintaining safety stock, businesses can protect their revenue streams and customer loyalty. For example, pharmaceutical companies maintain precise safety stock for life-critical medications, ensuring availability is never compromised by supply chain disruptions. Similarly, Apple carefully manages safety stock for new product launches to handle unpredictable initial demand surges.

How to Implement Safety Stock Optimisation

- Calculate Key Variables: You need three main data points: maximum daily sales, average daily sales, and average lead time. Accurate historical data is essential for this step.

- Use a Standard Formula: A common formula is: (Maximum Daily Sales × Maximum Lead Time) – (Average Daily Sales × Average Lead Time). This calculation provides a data-driven buffer stock level.

- Regularly Review and Adjust: Market conditions change. Regularly revisit your safety stock levels-at least quarterly-to account for new sales trends, supplier performance, and seasonal variations.

This methodical approach moves your inventory strategy from guesswork to a data-backed process. Consulting firms like McKinsey & Company often help large enterprises implement sophisticated statistical models to optimise these levels across thousands of SKUs, proving its value at any scale.

7. Vendor-Managed Inventory (VMI)

Shifting the burden of stock management can be a powerful strategic move. Vendor-Managed Inventory (VMI) is a collaborative supply chain practice where the supplier, not the retailer, takes full responsibility for maintaining inventory levels at the customer's location. This approach turns the traditional ordering process on its head, empowering vendors to monitor stock, forecast demand, and schedule replenishments proactively.

The core principle of VMI is to align the goals of the supplier and the customer. The supplier gains direct visibility into real-time demand and sales data, allowing for more efficient production planning and reduced forecasting errors. In return, the customer benefits from lower stockout risks, reduced administrative overhead, and minimised holding costs, as the supplier is incentivised to keep inventory lean but effective.

This model fosters a true partnership. For instance, Procter & Gamble famously pioneered VMI with Walmart in the 1980s, a move that revolutionised retail supply chains by ensuring products like nappies and detergents were consistently available. Similarly, Shell utilises VMI to manage lubricant stock at large industrial customer sites, guaranteeing operational continuity for their clients.

How to Implement Vendor-Managed Inventory (VMI)

- Establish a Strong Partnership: Start by selecting a trusted supplier. A successful VMI relationship is built on clear communication, shared goals, and mutual trust.

- Define Service Level Agreements (SLAs): Clearly document performance metrics, such as minimum and maximum stock levels, fill rates, and order lead times. This agreement ensures both parties understand their responsibilities and expectations.

- Integrate Data Systems: Set up a secure system for sharing real-time data, such as point-of-sale (POS) information, inventory levels, and demand forecasts. This data integration is crucial for the supplier to make informed replenishment decisions. Many modern ERP systems support these workflows as a form of business process automation.

- Start Small and Scale: Begin the VMI programme with a limited selection of non-critical items. This allows both your business and your vendor to refine the process, build confidence, and demonstrate value before expanding to more critical product lines.

8. Cycle Counting and Inventory Accuracy

Relying solely on an annual, wall-to-wall physical inventory count is an outdated practice that often leads to significant operational disruptions and prolonged inaccuracies. A more dynamic and effective approach is cycle counting, a continuous inventory auditing process where small subsets of inventory are counted on a rotating, regular schedule. This method is one of the most crucial inventory management best practices for maintaining high data accuracy without the costly downtime of a full-scale audit.

The core principle is to break down the daunting task of a full inventory count into manageable daily or weekly tasks. This ensures that inventory records are consistently verified and corrected, leading to more reliable data for purchasing, production planning, and sales. The benefits include:

- Minimal Disruption: Counts are integrated into daily warehouse operations, eliminating the need to shut down the business.

- Improved Accuracy: Frequent checks catch discrepancies early, preventing them from escalating and revealing systemic issues.

- Reduced Costs: Avoids the high labour costs and lost sales associated with annual physical counts.

- Better Decision-Making: Accurate, real-time inventory data empowers smarter purchasing and stocking decisions.

By regularly validating stock levels, businesses can trust their inventory management system, reduce carrying costs, and improve order fulfilment rates. This methodical approach is a cornerstone of lean manufacturing and modern warehouse management, transforming inventory auditing from a dreaded annual event into a value-adding daily routine.

How to Implement Cycle Counting

- Segment Your Inventory: Use a method like ABC analysis to categorise items. High-value, fast-moving 'A' items should be counted more frequently (e.g., monthly), while low-value 'C' items can be counted less often (e.g., biannually).

- Establish a Schedule: Create a realistic and consistent counting schedule based on your segmentation. Assign specific items or locations to be counted each day or week.

- Investigate and Correct: When discrepancies are found, don't just adjust the numbers. Investigate the root cause, whether it's theft, receiving errors, or process failures. This is a key part of business process improvement on kpinfo.tech.

- Track and Measure: Monitor inventory accuracy over time. Key metrics like Inventory Record Accuracy (IRA) will show the effectiveness of your cycle counting programme and highlight areas needing improvement.

Global giants like Amazon use sophisticated, technology-driven cycle counting in their fulfilment centres to maintain near-perfect inventory accuracy across millions of SKUs. Similarly, hospitals rely on this method to ensure critical medical supplies are always available, demonstrating its versatility and importance across different industries.

9. Cross-docking and Flow-through Distribution

Holding stock in a warehouse is a significant cost factor, tying up capital and space. Cross-docking is one of the most dynamic inventory management best practices designed to nearly eliminate this cost. It is a logistics procedure where products from a supplier or manufacturing plant are distributed directly to a customer or retail chain with minimal to no handling or storage time.

Instead of being stored, incoming goods are sorted, consolidated, and immediately loaded onto outbound lorries. This “flow-through” approach dramatically reduces inventory holding costs, shortens delivery lead times, and minimises the risk of product damage from excessive handling. It is particularly effective for high-volume, fast-moving consumer goods and perishable items where speed to market is critical.

This method streamlines the supply chain by turning the distribution centre into a sorting hub rather than a long-term storage facility. For instance, global retailers like Walmart have famously used cross-docking to replenish stores rapidly, ensuring popular products are always available. Similarly, logistics giants such as FedEx and UPS rely on this model to sort and route millions of packages efficiently through their hubs every day.

How to Implement Cross-docking

- Establish Strong Partnerships: Success depends on tight coordination. Ensure your suppliers can deliver goods on a precise schedule and that shipments are pre-sorted and correctly labelled to facilitate immediate transfer.

- Invest in Technology: Use an advanced warehouse management system (WMS) or transportation management system (TMS) to provide real-time visibility into inbound and outbound shipments, enabling precise scheduling and coordination.

- Start with Suitable Products: Begin by implementing cross-docking for your most predictable, high-turnover products. These items provide a stable flow that is easier to manage before expanding the strategy to more variable inventory.

- Optimise Dock Layout: Design your warehouse dock area to support a seamless flow from inbound to outbound doors. This includes clear signage, adequate staging areas, and efficient material handling equipment placement to prevent bottlenecks.

Inventory Management Best Practices Comparison

| Inventory Method | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| ABC Analysis for Inventory Prioritization | Low to moderate 🔄 | Moderate (data analysis tools) ⚡ | Focused resource allocation, improved cash flow 📊 | Prioritizing inventory by revenue impact 💡 | Simplifies control, optimizes resource use ⭐ |

| Just-in-Time (JIT) Inventory Management | High 🔄 | High (supplier coordination) ⚡ | Reduced carrying costs, minimized waste 📊 | Lean manufacturing, demand-driven environments 💡 | Cuts costs, improves efficiency, reduces waste ⭐ |

| Economic Order Quantity (EOQ) Optimization | Moderate 🔄 | Moderate (cost data, software) ⚡ | Minimized total inventory costs, clear reorder points 📊 | Stable demand environments, cost-optimization 💡 | Scientific cost minimization, reduces errors ⭐ |

| Demand Forecasting and Planning | High 🔄 | High (analytics, data integration) ⚡ | Better inventory and production planning 📊 | Complex, seasonal, or trend-driven demand scenarios 💡 | Improves accuracy, reduces stockouts ⭐ |

| Real-time Inventory Tracking and Visibility | High 🔄 | High (technology investment) ⚡ | Accurate, up-to-date inventory information 📊 | Multi-location, fast-moving inventory environments 💡 | Improves accuracy, enables quick response ⭐ |

| Safety Stock Optimization | Moderate 🔄 | Moderate (data and modeling tools) ⚡ | Balanced service levels and costs 📊 | Managing demand/supply variability and risk 💡 | Prevents stockouts, optimizes buffer inventory ⭐ |

| Vendor-Managed Inventory (VMI) | High 🔄 | Moderate to high (collaboration tools) ⚡ | Reduced workload, improved supplier collaboration 📊 | Supplier-managed replenishment environments 💡 | Lowers inventory burden, leverages supplier expertise ⭐ |

| Cycle Counting and Inventory Accuracy | Moderate 🔄 | Moderate (staff time, systems) ⚡ | High inventory accuracy, reduced disruptions 📊 | Continuous inventory auditing and control 💡 | Maintains accuracy year-round, reduces shutdowns ⭐ |

| Cross-docking and Flow-through Distribution | High 🔄 | High (transportation and systems) ⚡ | Reduced inventory holding time, faster delivery 📊 | Fast-paced logistics requiring minimal storage 💡 | Cuts costs, speeds up flow, reduces handling ⭐ |

From Theory to Action: Implementing Your Modern Inventory Strategy

Navigating the complexities of modern commerce requires more than just having products on a shelf; it demands a sophisticated, strategic approach to managing them. Throughout this guide, we have explored a suite of powerful inventory management best practices, from the granular prioritisation of ABC analysis to the fluid efficiency of cross-docking. We have seen how methods like Just-in-Time (JIT) can drastically reduce carrying costs and how robust demand forecasting can prevent the dual pitfalls of stockouts and overstocking. Each practice represents a tool designed to bring precision, predictability, and profitability to your operations.

The overarching theme is a fundamental shift in perspective. Effective inventory management is no longer a static, reactive function confined to the warehouse. Instead, it is a dynamic, data-driven engine that powers the entire business. It influences cash flow, customer satisfaction, operational efficiency, and your ability to scale. Embracing these principles means moving away from guesswork and historical habits towards a system where decisions are backed by real-time data and strategic intent.

Your Actionable Roadmap to Inventory Excellence

Adopting these advanced frameworks can seem daunting, but progress is achieved through a measured, iterative approach, not a complete overhaul overnight. The key is to build a customised strategy that aligns with your unique business model, product lifecycle, and customer demands.

Here is a practical roadmap to get started:

- Conduct a Diagnostic Audit: Before implementing new systems, understand your current state. Where are the most significant pain points? Are you struggling with high carrying costs? Frequent stockouts of high-demand items? Inaccurate inventory counts? Use this analysis to identify which of the discussed practices will deliver the most immediate impact. For instance, if inaccuracy is your biggest challenge, start with cycle counting.

- Start Small and Build Momentum: You do not need to implement everything at once. Select one or two complementary practices to begin. A powerful starting combination is ABC analysis paired with safety stock optimisation. This allows you to focus your resources on your most valuable products (your 'A' items) while creating a buffer against uncertainty, delivering a quick and measurable win.

- Prioritise Data and Technology: Modern inventory management is impossible without the right technological foundation. Manual spreadsheets and disparate systems are prone to error and cannot provide the real-time visibility needed for methods like JIT or VMI. The goal is to create a single source of truth for your inventory data.

- Embrace Continuous Improvement: The market is not static, and neither should your inventory strategy be. Regularly review your performance metrics. Is your EOQ formula still accurate? Has customer demand shifted? Are your safety stock levels appropriate for current lead times? Cultivating a culture of continuous improvement ensures your operations remain agile and resilient.

Ultimately, mastering these inventory management best practices transforms your stock from a simple asset into a strategic advantage. It allows you to build a more responsive supply chain, enhance customer loyalty through reliable fulfillment, and unlock capital that can be reinvested into growth. By moving from theory to deliberate action, you build a resilient operational backbone capable of supporting your business today and scaling with it tomorrow.

Ready to replace fragmented spreadsheets with a powerful, integrated system? The experts at KP Infotech specialise in developing custom ERP and Odoo solutions that automate these best practices, providing the real-time visibility and control you need to optimise your inventory. Discover how KP Infotech can build the inventory management system your business deserves.