Let’s cut through the jargon. What is digital engineering, really?

At its heart, digital engineering is a complete mindset shift. It’s about moving away from stacks of paper blueprints and disconnected spreadsheets and embracing an integrated approach that uses digital models and data as the primary language for a project. This creates a single, authoritative source of truth that connects every single stage of a system’s life, from the first sketch to its last day in service.

What Is Digital Engineering Really

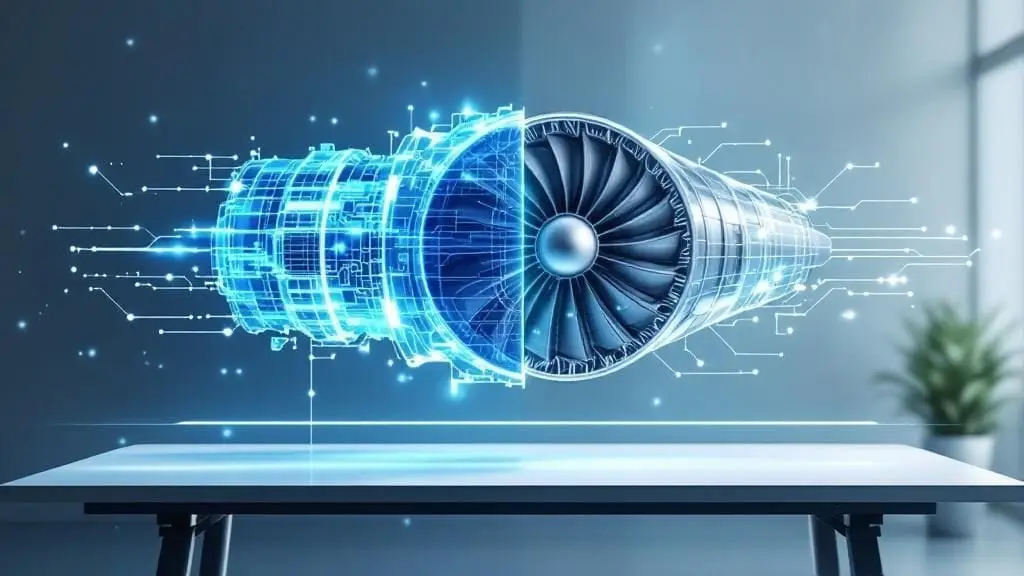

Picture this: instead of building a complex jet engine with physical metal and bolts, you first build it with intelligent, interconnected digital blocks. That’s the essence of digital engineering. It fundamentally changes how products are developed, pulling teams out of their silos and into a collaborative, model-centric world.

This single, living digital model becomes the definitive playbook for the entire project.

This "single source of truth" isn't a static file; it's a living, breathing entity that evolves. It starts with the first spark of an idea and grows through design, manufacturing, testing, and even ongoing operations. By creating this continuous digital thread, you ensure everyone—from designers to maintenance crews—is working from the same, up-to-the-minute information.

From Blueprint to Digital Thread

The real transformation is leaving behind static documents that are outdated the moment they're printed. Traditional engineering gets bogged down by separate drawings, spreadsheets, and reports that are a nightmare to keep in sync. Make one change here, and you have to manually hunt down and update countless other files, opening the door for costly errors and delays.

Digital engineering swaps this fragmented mess for a dynamic, interconnected ecosystem. This shift gives teams a complete, holistic picture of a system long before any physical parts are ever made. It allows them to spot and fix problems in the virtual world, where changes are fast and cheap.

To see how this works in practice, let's compare the old way with the new.

Traditional vs Digital Engineering at a Glance

This table breaks down the fundamental differences between the two approaches, showing just how deep the shift really is.

| Aspect | Traditional Engineering | Digital Engineering |

|---|---|---|

| Primary Medium | Paper blueprints, 2D drawings, static documents | Interactive 3D models, data streams, digital twins |

| Source of Truth | Fragmented across multiple documents and teams | A single, authoritative, and integrated digital model |

| Workflow | Linear and sequential (waterfall approach) | Iterative, concurrent, and collaborative (agile) |

| Collaboration | Siloed departments with formal handoffs | Cross-functional teams working on a shared model |

| Issue Resolution | Discovered late, during physical prototyping | Identified early in the virtual design phase |

| Lifecycle Data | Disconnected and often lost between phases | A continuous "digital thread" from concept to disposal |

The table makes it clear: this isn't just about using new software. It’s a cultural shift in how teams collaborate and share information. The team here at KP Infotech has seen firsthand how this integrated approach can completely reshape an organization's capabilities.

"At its core, digital engineering is about generating models and structured data to capture engineering solutions. The digital thread integrates that data within and across engineering domains to ensure consistency, traceability, and completeness of designs."

This transition is a massive part of any successful digital transformation. Getting it right often means tackling broader organizational hurdles. For anyone navigating this change, understanding resources for overcoming digital transformation challenges can provide some much-needed context.

By embracing this model-based future, companies can build more complex, reliable products faster and with far less risk.

Understanding the Pillars of Digital Engineering

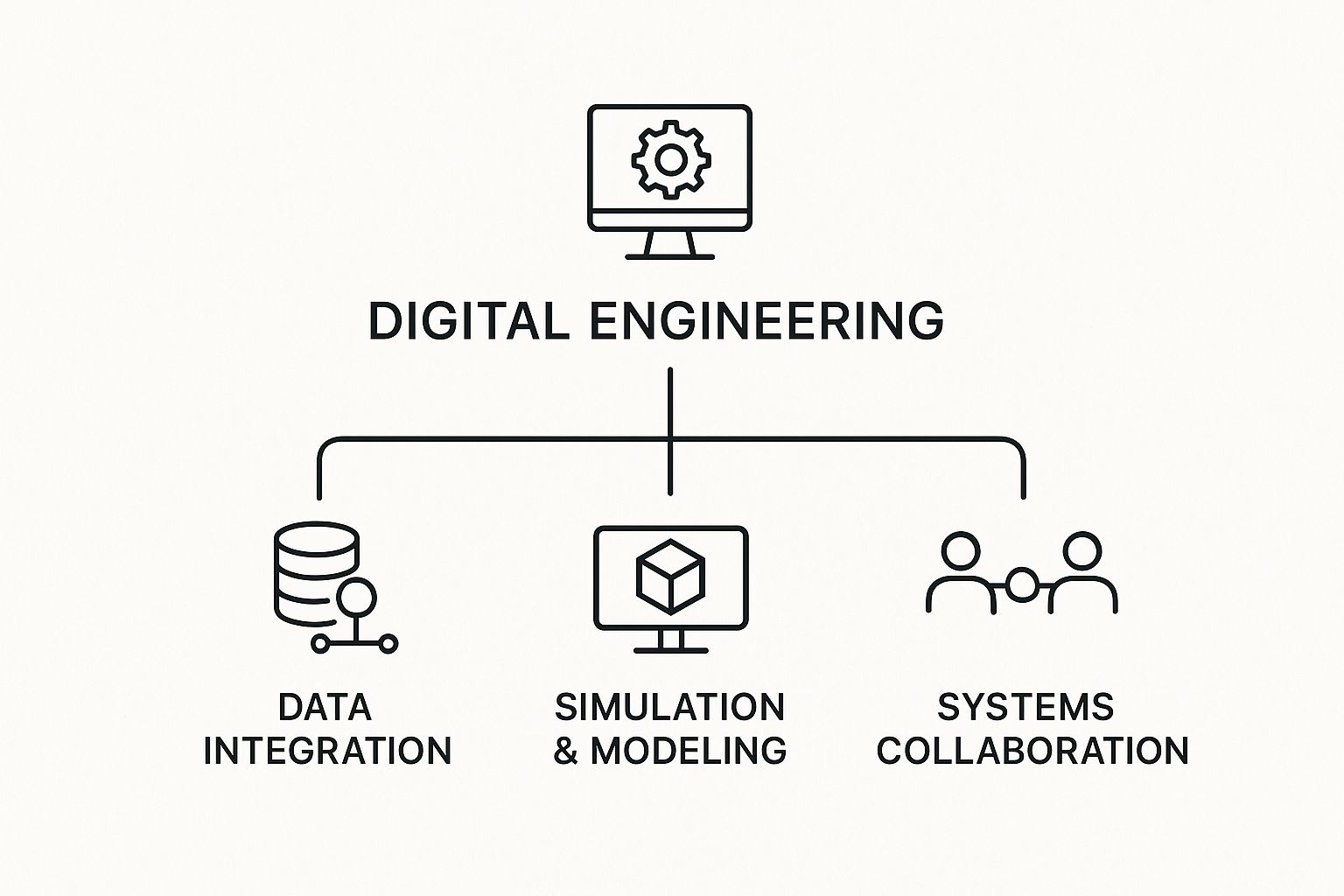

Digital engineering isn't a single piece of tech you can just buy and install. It’s more like a powerful ecosystem, a way of thinking and working built on three interconnected pillars. When they work together, they create a seamless, intelligent flow of information that brings virtual designs to life with a level of accuracy and speed we just couldn't achieve before.

Each pillar has its own distinct job, but they’re all designed to complement one another in this modern approach to building things.

Model-Based Systems Engineering (MBSE)

The first pillar is Model-Based Systems Engineering (MBSE). The best way to think of MBSE is as the master blueprint for a project. Instead of passing around static documents and drawings that are outdated the second they’re printed, MBSE uses a single, unified set of digital models to lay out a system's requirements, architecture, and behavior.

These models are all connected. That means a change in one area automatically ripples through and updates all the related parts, which keeps the entire design consistent. It provides a structured, formal language that everyone—from the software team to the mechanical engineers—can understand and work from. It's the foundation that makes sure everyone is building toward the same, clearly defined goal.

The Digital Twin and Digital Thread

Next up is the Digital Twin, a dynamic, living virtual copy of a physical product or system. This is so much more than a simple 3D model. A digital twin is wired into its real-world counterpart, constantly fed with data from sensors. This live link allows engineers to run simulations, test performance under insane conditions, and even predict when maintenance is needed, all without ever touching the physical asset.

Imagine an aerospace company using a digital twin of a new jet engine. They can simulate how it will hold up in freezing temperatures or extreme turbulence, flagging potential problems long before a single piece of metal is cut.

The final pillar is the Digital Thread, which is the central nervous system connecting everything. It's the continuous, unbreakable trail of data that weaves through every single stage of a product's life—from the first sketch to design, manufacturing, operation, and all the way to retirement. This thread stitches together the MBSE models, the digital twin data, and every other bit of critical information into one traceable record.

The digital thread should seamlessly advance the controlled interplay of technical data, software, information, and knowledge in the digital engineering ecosystem. It provides the capability to access, integrate, and transform data into actionable information.

This integrated framework is absolutely critical for managing complexity in modern projects. To really get a feel for how these pieces fit together, it helps to see how various new technologies in manufacturing for innovation are being applied in similar ways. Together, these three pillars—MBSE, the Digital Twin, and the Digital Thread—are the heart of digital engineering.

This infographic breaks down the core functional areas where these pillars really shine.

As you can see, the whole point is to achieve deep data integration, build advanced models, and foster collaboration across the entire system.

Driving Growth Across Industries

This isn't just a theoretical upgrade; the move toward digital engineering is a serious economic driver. We're seeing this approach cause massive expansion across mission-critical industries, and the spending growth rates show it’s becoming central to future development.

Investment research shows that digital engineering spending is expected to grow at a CAGR of roughly 18% through 2028. Industries like aerospace and defense are already huge markets, estimated somewhere between USD 90 billion and USD 120 billion, and they’re growing by 7–8% every year.

This massive investment points to a fundamental shift in how things are done. Companies get it now: to stay in the game, they have to build better, faster, and more efficiently. A key part of this is integrating these digital tools with core business operations, which is why a solid enterprise resource planning software is so often a critical piece of any successful digital transformation strategy.

How AI Is Transforming Digital Engineering

Artificial Intelligence is no longer just a tool for crunching numbers after the fact. It’s now an active, intelligent partner baked right into the engineering and design process. This goes way beyond simple automation; AI is fundamentally changing how engineers tackle complex problems and imagine what’s possible.

Think of it this way: the digital thread generates an ocean of data. AI is the engine that can actually make sense of it all, uncovering insights a human team could never spot on its own. If a digital twin is the living, breathing replica of a product, AI is the brain interpreting its every move. It can spin up thousands of simulations at once, learning from each cycle to predict outcomes and fine-tune performance on the fly.

The Rise of Generative Design and Agentic AI

One of the most mind-bending applications of AI is generative design. Here, an engineer doesn't painstakingly draw a solution. Instead, they give the AI a set of goals and guardrails—things like materials, weight limits, and manufacturing methods.

The AI then gets to work, exploring thousands or even millions of design possibilities to find the best solutions. It often comes up with incredibly efficient, organic-looking shapes that a human designer would likely never conceive.

This is where Agentic AI enters the scene, and it’s a massive leap forward. These are intelligent, autonomous agents that can carry out complex engineering tasks with very little human supervision.

Agentic AI applications are set to dramatically expand engineering capabilities through advanced automation and autonomous decision-making. This shift isn't just an incremental improvement; it's a fundamental change in how engineering work gets done.

The growth projected for this space is just staggering. The global Agentic AI market in digital engineering is expected to explode from USD 3.4 billion to an incredible USD 378.5 billion by 2034. That’s a compound annual growth rate of 60.2%. You can explore the full market analysis on Market.us to dig deeper into this trend.

AI-Powered Predictive Maintenance

AI’s job doesn’t stop once a product is designed and built. It plays a huge role throughout its operational life. By continuously analyzing real-time data streaming from a digital twin’s sensors, AI algorithms can pick up on subtle patterns and anomalies that signal a failure is on the horizon.

This makes predictive maintenance possible—a proactive strategy where repairs are scheduled exactly when they’re needed, not on a rigid schedule or after a catastrophic breakdown.

This capability delivers some serious benefits:

- Reduces Unplanned Downtime: By forecasting failures before they happen, companies can sidestep costly operational shutdowns.

- Optimizes Resource Allocation: Maintenance crews and spare parts are only deployed when necessary, which saves a ton of time and money.

- Extends Asset Lifespan: Proactive care keeps equipment running in peak condition, squeezing more service life out of every asset.

Ultimately, plugging AI into digital engineering isn't just about speed. It’s about giving engineers the power to solve problems that were previously unsolvable, augmenting human creativity with immense computational power to push the boundaries of innovation.

The Real-World Benefits of Digital Engineering

Beyond the cool tech and fancy models, digital engineering delivers real, game-changing advantages that hit the bottom line. It’s a strategic shift that completely changes how companies compete, letting them design, build, and maintain products with a level of speed and accuracy that was impossible before. This isn't just about making better blueprints; it's about fundamentally smarter business.

The most obvious win is a massive leap forward in innovation. In a traditional workflow, building and testing a single physical prototype can burn through months and a small fortune. Digital engineering lets teams run thousands of virtual tests in the digital world in just a fraction of that time.

This rapid-fire iteration process opens the door for more creative problem-solving and fine-tuning, drastically cutting down time-to-market. Better yet, the final product is far more robust and reliable from day one.

Driving Down Costs and Project Risks

One of the biggest money pits in any complex project is discovering a mistake way too late. A tiny design error found during physical assembly can set off a chain reaction of expensive rework and soul-crushing delays. Digital engineering flips this entire model on its head by finding those problems early.

By catching design flaws, material conflicts, and integration headaches in the virtual world, companies can stop these issues from ever reaching the factory floor. A huge real-world benefit here is the ability to perform advanced Clash Detection and Coordination, a process that spots where things like pipes or wiring might interfere with steel beams before a single piece of material is ordered. This kind of virtual troubleshooting saves an incredible amount of time and money.

Digital engineering allows you to understand the problem before the system is built. This approach not only reduces costs but also significantly increases effectiveness by resolving issues when they are cheapest to fix—in the digital space.

Enhancing Team Collaboration and Lifecycle Management

Siloed teams are a classic project-killer. When mechanical, electrical, and software engineers are all working off separate plans, misunderstandings and integration failures are practically a sure thing. Digital engineering smashes down those walls by creating a single, authoritative digital model that everyone works from.

This single source of truth makes sure every team is aligned and building toward the same goal from the very beginning. It fosters a truly collaborative space where changes made by one group are instantly visible to everyone else, leading to a much more cohesive and efficient workflow.

This complete view stretches across the entire product lifecycle:

- Smarter Maintenance: Digital twins, fed with real-time data from the physical world, enable predictive maintenance, slashing costly unplanned downtime.

- Targeted Upgrades: Engineers can simulate and test software updates or new components on the digital model before deploying them to the physical asset.

- Sustainable Planning: Lifecycle data helps companies plan for more sustainable end-of-life decommissioning and material recycling.

As engineering and IT functions continue to merge, it’s critical to anticipate future operational needs. Keeping an eye on emerging IT support trends for 2025 helps organizations get ready for the demands of managing these complex digital ecosystems.

To wrap it all up, let's look at the core advantages in a clear, straightforward way.

Key Benefits of Digital Engineering Implementation

The table below summarizes the primary advantages organizations can expect from adopting a digital engineering strategy.

| Benefit Category | Description | Example Impact |

|---|---|---|

| Speed & Innovation | Dramatically shortens design, testing, and iteration cycles through virtual simulation instead of physical prototypes. | A car manufacturer simulates 10,000 crash scenarios in a week, a process that would take years physically. |

| Cost Reduction | Identifies and resolves design flaws, material conflicts, and integration issues early in the digital phase. | An aerospace company saves $1.2 million in rework by catching an engine mount conflict in the digital twin. |

| Risk Mitigation | Provides a comprehensive, data-driven view of the entire system, reducing unforeseen problems during production. | Construction firm avoids a 6-week delay by identifying HVAC and plumbing clashes virtually before construction starts. |

| Improved Collaboration | Creates a single source of truth (e.g., a digital twin) that all teams can access, ensuring everyone is aligned. | Cross-functional teams (mechanical, electrical, software) work on the same model, reducing integration errors by 40%. |

| Lifecycle Management | Enables predictive maintenance, targeted upgrades, and sustainable planning through a continuously updated digital model. | A wind farm uses its digital twin to predict turbine failures, increasing uptime by 15% and reducing maintenance costs. |

Ultimately, adopting digital engineering isn't just an upgrade—it's a foundational shift that equips a business to be more agile, efficient, and competitive.

Digital Engineering in Action Across Industries

It's one thing to talk about digital engineering in theory, but where does the rubber actually meet the road? This isn't some far-off concept—it’s a hands-on strategy that’s already delivering real results in some of the world's most demanding industries.

From the sky to the factory floor, companies are using digital engineering to solve high-stakes problems and gain a serious competitive edge. Let’s look at a few examples.

Aerospace and Defense

When you’re building an aircraft, there's zero room for error. That’s why aerospace companies now build complete digital twins of new planes before a single piece of metal is cut. These virtual models let engineers simulate thousands of flight scenarios, from hitting severe turbulence to handling an engine failure.

These virtual tests are absolutely crucial for:

- Stress Testing: Simulating decades of wear and tear on a component in just a few days to find weak spots early.

- Systems Integration: Making sure the complex web of avionics, hydraulics, and software all play nicely together under pressure.

- Predictive Maintenance: Using live data from planes in the air to predict when a part might fail and scheduling repairs before it becomes a problem.

Automotive Innovation

The car industry is another hotbed for digital engineering, especially as autonomous vehicles become a reality. Automakers are designing, building, and road-testing incredibly complex self-driving systems entirely within a simulated world.

A digital model lets engineers test millions of miles of driving, including rare and dangerous "edge cases" that would be impossible—and unsafe—to recreate on public roads.

This digital proving ground is the key to training driving AI and proving it's safe and reliable. Before a self-driving car ever hits the pavement, its digital counterpart has already navigated countless virtual hazards, ensuring it knows how to respond when it matters most.

Advanced Manufacturing and Production

On the factory floor, efficiency is the name of the game. Modern manufacturers are creating detailed digital replicas of their entire production lines. These "virtual factories" allow them to test new layouts, run "what-if" scenarios, and pinpoint bottlenecks without ever having to shut down the real assembly line.

The results are huge improvements in both output and quality. It's no surprise that the market is taking notice. The global digital product engineering services market, valued at around USD 2.24 billion recently, is expected to climb to about USD 3.12 billion by 2032. This growth makes it clear how essential these digital strategies have become. You can learn more about these digital engineering service market trends from Intel Market Research.

These examples aren’t science fiction. They show that digital engineering is here now, solving tough problems and delivering value you can measure.

Common Questions About Digital Engineering

As digital engineering moves from a niche concept to a core business strategy, a lot of practical questions start to pop up. It’s one thing to understand the theory, but another to see how it fits into your day-to-day work. Let's tackle some of the most common questions to clear up how digital engineering actually works in the real world.

Digital Engineering vs. Model-Based Engineering

What's the difference between digital engineering and model-based engineering (MBE)? This one comes up all the time, and it's a major point of confusion, but the relationship is actually pretty simple.

Think of it this way: Model-Based Engineering (MBE) is a specific technique, while digital engineering is the entire strategic game plan. MBE is the practice of using detailed digital models—not old-school paper drawings—as the main source of truth for technical information. It’s a foundational piece of the puzzle.

Digital Engineering, on the other hand, is the whole ecosystem. It absolutely uses MBE, but it also pulls in the digital thread, digital twins, and all the infrastructure needed to manage a product from the first sketch to its final day in service. In short, MBE is a critical part of the much bigger digital engineering picture.

"At its core, digital engineering is about generating models and structured data to capture engineering solutions. The digital thread integrates that data within and across engineering domains to ensure consistency, traceability, and completeness of designs."

This distinction is key. Adopting digital engineering isn’t just about switching to 3D models; it’s about rethinking your entire information flow from the ground up.

Is Digital Engineering Only for Large Companies?

Is this whole approach just for massive aerospace and automotive giants? Not anymore. While those industries were definitely the early pioneers—mostly because their products are incredibly complex—that's no longer the reality.

The tools and principles behind digital engineering are now far more affordable and scalable. This has swung the door wide open for small and medium-sized businesses (SMBs) to get in on the action and see the same kinds of benefits.

Today, you'll find companies across all sorts of industries putting these strategies to work:

- Consumer Electronics: Using virtual prototypes to design and test new gadgets faster than ever.

- Medical Devices: Simulating how a device will perform and even running virtual trials to meet tough regulatory hurdles.

- Construction: Using digital models to spot clashes between plumbing and electrical systems before a single shovel hits the dirt.

The truth is, any company that deals with complex product development can find a serious competitive edge here.

How to Start Implementing a Digital Engineering Strategy

Okay, so where do you start? It can feel like a massive undertaking, but the secret is to start small and score a quick win. Trying to overhaul everything at once is usually a recipe for disaster. Instead, pick a focused pilot project—maybe for a single product line or to fix one specific broken process.

A successful launch usually boils down to a few key steps:

- Assess Your Workflow: First, figure out where the real pain is. Where do the most expensive mistakes happen? What are your biggest delays? Start there.

- Set a Clear Goal: Give your pilot a measurable target. Something concrete, like "cut down design rework by 20%" or "slash our prototyping costs by 30%."

- Choose the Right Tools: Pick the technology that solves the specific problem you identified. Don’t get mesmerized by flashy features you don't actually need yet.

- Invest in Your Team: This is the most important step. Your people are the ones who will make this work. Train your engineers and designers and give them the digital skills they need to succeed.

A successful pilot does more than just fix a problem. It becomes a powerful proof of concept that shows real, tangible value to leadership. Just as importantly, it teaches you invaluable lessons that will help you roll out the strategy more broadly with confidence.

Ready to transform your development lifecycle? KP Infotech provides end-to-end digital transformation services that can guide your organization's journey into digital engineering. Learn how we can help you build the future, today.