The Uncomfortable Truth About ERP Implementation Failures

Imagine investing a huge amount of your company's resources into a new Enterprise Resource Planning (ERP) system. The sales pitch promises a perfect future where information flows seamlessly across all departments, driving efficiency and offering clear, actionable insights. The reality, however, is that many of these ambitious projects don't end in celebration. Instead, they often fizzle out, leaving behind drained budgets and frustrated teams. This isn't just about a few technical bugs; it's a complicated mix of human factors, mismatched expectations, and underestimating the sheer size of the undertaking.

The numbers tell a story that's hard to ignore. Some industry analyses reveal that ERP implementation failure rates can be as high as 55% to 75%. This means most projects miss their targets for budget, timeline, and functionality. A major reason for this is the failure to deliver the expected return on investment (ROI), which can cause projects to be scrapped or to change so much that they barely resemble the original plan. You can read more about the challenges of delivering expected ROI in these project analyses.

The Gap Between Vendor Promises and Harsh Reality

One of the most frequent ERP implementation issues arises from the disconnect between a vendor’s polished sales presentation and the messy truth of putting it into practice. Vendors are skilled at showing you a best-case scenario where their software is the answer to every problem. What they can't fully prepare you for are your company's unique internal processes, office politics, or the quality of your existing data.

Executives, eager for a quick fix, can fall into a trap of optimism bias, believing their company will be the one to get it right against the odds. They see the slick demos and hear the grand promises, underestimating the immense effort required from their own people. This isn't about placing blame; it's about acknowledging a natural gap. The vendor sells the destination—a fully working ERP—but your team has to handle the difficult journey to get there, which means dealing with every unexpected problem along the way.

Early Warning Signs of a Failing Project

Spotting trouble early is essential. Simply throwing more money at a struggling project is like using a small bandage on a major wound—it won't fix the underlying issue. Here are some early indicators that your implementation might be in trouble:

- Key stakeholders are disengaged: If department heads or crucial end-users are regularly skipping meetings or not providing feedback, it's a major red flag. Their involvement is not optional; it's a core requirement for the project's success.

- The project scope keeps expanding: Constant requests for "just one more feature" might seem minor on their own, but together they cause scope creep. This bloats the project's timeline and budget, pushing it off course.

- Decisions are constantly delayed: When decisions on key process changes or system configurations are put off, progress grinds to a halt. This often points to a lack of clear leadership or agreement among the team.

A great first step is to understand what a modern system is made of. You can check out our detailed overview of ERP software to get a solid grasp of what these systems involve. This background helps you appreciate the project's complexity and why these warning signs are so important to watch for.

When Million-Dollar Investments Become Cautionary Tales

The dry statistics on ERP failures don't truly convey the sheer chaos of a botched project. These systems aren't just expensive software; they're the new central nervous system of a company. When this system fails, it can freeze the entire organization, turning a hopeful investment into a high-profile disaster. The problems are rarely isolated, creating a devastating ripple effect that touches every department. Can you imagine your sales team unable to process an order or your finance department unable to close the books for months?

These aren't hypothetical situations. They are real-world disasters that have pushed companies to their limits. One of the most common erp implementation issues is how seemingly small missteps at the beginning can grow into catastrophic failures. A minor hiccup in migrating data can corrupt thousands of customer records. An overlooked gap in a business process can make a whole workflow useless, pushing employees back to manual spreadsheets—the very inefficiency the ERP was bought to solve.

Anatomy of a High-Profile Failure

These major failures often become public, serving as stark warnings for others. Consider the case of Marin County, California, which invested around $18.6 million into an ERP system from SAP meant to handle its HR and finance operations. The rollout was so disastrous that for two years, the county could not perform basic financial tasks. The project was eventually abandoned, resulting in a $30 million lawsuit against the vendor and an additional $5 million in legal fees. You can discover more insights about this costly ERP project failure on pemeco.com.

The Domino Effect of a Failed Go-Live

The initial project failure is often just the start of the pain. The operational breakdown that follows erodes both employee morale and customer confidence. Here’s how the problems typically stack up:

- Operational Paralysis: Essential functions like invoicing, payroll, and managing inventory simply stop working. Without a dependable system, the business grinds to a halt.

- Employee Frustration and Turnover: Staff become demoralized trying to use awkward, broken tools. They are forced to work longer hours on manual fixes, which leads to burnout and people quitting.

- Reputation Damage: When a company can't fulfill orders or pay its suppliers on time, its reputation takes a major hit. Customers and partners lose faith, a trust that can take years to earn back.

The hard truth is that recovering from a major ERP failure is often a longer and more expensive process than the original implementation. It involves more than just fixing technical glitches; it requires rebuilding lost trust and momentum across the entire company. This is why understanding the critical moments where projects go wrong is so important. A single bad decision in planning, vendor choice, or managing change can trigger a chain reaction with consequences that last for years.

Why Your Team Holds The Key To ERP Success

While it's easy to blame software glitches for project troubles, the most common and damaging ERP implementation issues aren't technical—they're human. A flawlessly coded system is worthless if the people meant to use it don't understand it, feel resentful, or actively resist it. Your project's outcome relies less on the technology and more on your team's readiness to adopt a new way of working. This is where many companies stumble, fixating on technical details while overlooking their employees' emotional journey.

Resistance isn't always obvious. It can show up as skipped training sessions, quiet complaints, or employees reverting to old spreadsheets because "it's just faster." This opposition often comes from a fear of the unknown. People worry about job security, thinking automation might make them redundant. They also fear losing the expertise they've built over years, which makes them reluctant to let go of familiar routines. When leadership ignores these genuine human concerns, the project is set up for a struggle.

The Critical Role of Change Management

This is exactly why change management is not just a "nice-to-have" but a core part of the project. It’s more than sending a few update emails. Real change management is a planned effort to guide your team through the shift. It's about explaining the "why" behind the new system, not just the "how," and building a team of advocates at every level to champion the project.

The numbers tell a clear story about its importance. A staggering 60% of ERP projects fail to meet their objectives. Of those that fail, an incredible 95% of companies dedicated less than 10% of their total budget to training, education, and change management. This points to a major disconnect: organizations spend millions on software but skip the much smaller investment in their people needed to make it successful. You can find more statistics on how underfunding training leads to ERP failure on erpfocus.com.

To put this in perspective, here’s a look at how investing in your team directly correlates with project outcomes.

| Investment in Change Management vs. Success Rates |

|---|

| Comparison of budget allocation for training/change management and corresponding project success rates |

| Change Management Investment |

| Less than 5% of Budget |

| 5% – 10% of Budget |

| 10% – 15% of Budget |

| Over 15% of Budget |

As the table shows, there's a direct link between what you invest in preparing your people and the results you get. A small increase in the change management budget can dramatically improve success rates, user happiness, and the return on your investment.

From Compliance to Genuine Buy-In

Getting your team on board means going beyond mandatory training sessions. True success is achieved when you build genuine buy-in, where employees view the new ERP as a helpful tool rather than a burden. To make this happen, try these approaches:

- Involve End-Users Early and Often: Don't wait to show them the finished product. Bring key users from various departments into the selection and setup process. When people help build the solution, they feel a sense of ownership.

- Create Project Champions: Find influential employees in each department and empower them to be project advocates. Their support is often more convincing to their peers than instructions from management.

- Communicate Transparently and Honestly: Acknowledge that the transition will have its bumps. Be upfront about possible disruptions and have a clear support plan ready for when issues arise.

In the end, your company's culture will either boost or block your implementation. As you map out your project, it's also wise to think about the larger tech environment your team will face; knowing the key IT support trends for 2025 can help you prepare for what's next. By putting your people first, you transform your biggest potential weakness into your most powerful advantage.

Planning Mistakes That Sabotage Even Well-Intentioned Projects

Even with a strong team and executive backing, many ERP projects are undermined by subtle but damaging planning mistakes. These aren't huge, obvious blunders but small miscalculations that add up over time, creating significant ERP implementation issues. Think of it like building a house on a slightly uneven foundation; everything seems fine at first, but cracks are sure to appear as you add more weight. This often stems from a fuzzy understanding of business goals, an incomplete review of existing workflows, and putting too much trust in a vendor's initial pitch.

The Slow Poison of Scope Creep

One of the most dangerous planning failures is scope creep. It doesn't happen in a single, dramatic moment. Instead, it’s a slow drip of seemingly small requests: "Can we add just one more report?" or "Could the system also manage this one tiny process?" Each request on its own feels reasonable, but together they stretch the project's original boundaries, draining resources and pushing back deadlines. Before you know it, the project is over budget and behind schedule, trying to solve problems it was never meant to address. This is a common outcome when initial requirements aren't clearly defined with input from all affected departments.

Why Vendor Demos and Timelines Can Be Deceiving

Another common trap is placing absolute faith in vendor demonstrations and their estimated timelines. A vendor’s goal is to present their software in the most favorable way, using clean data in a perfect, controlled setting. This polished performance can easily hide the real-world complexities your business will encounter during the actual rollout. Likewise, the timelines they provide are usually best-case scenarios. They rarely factor in delays from data cleansing, unexpected integration hurdles, or the simple reality that your team still has to manage their daily responsibilities.

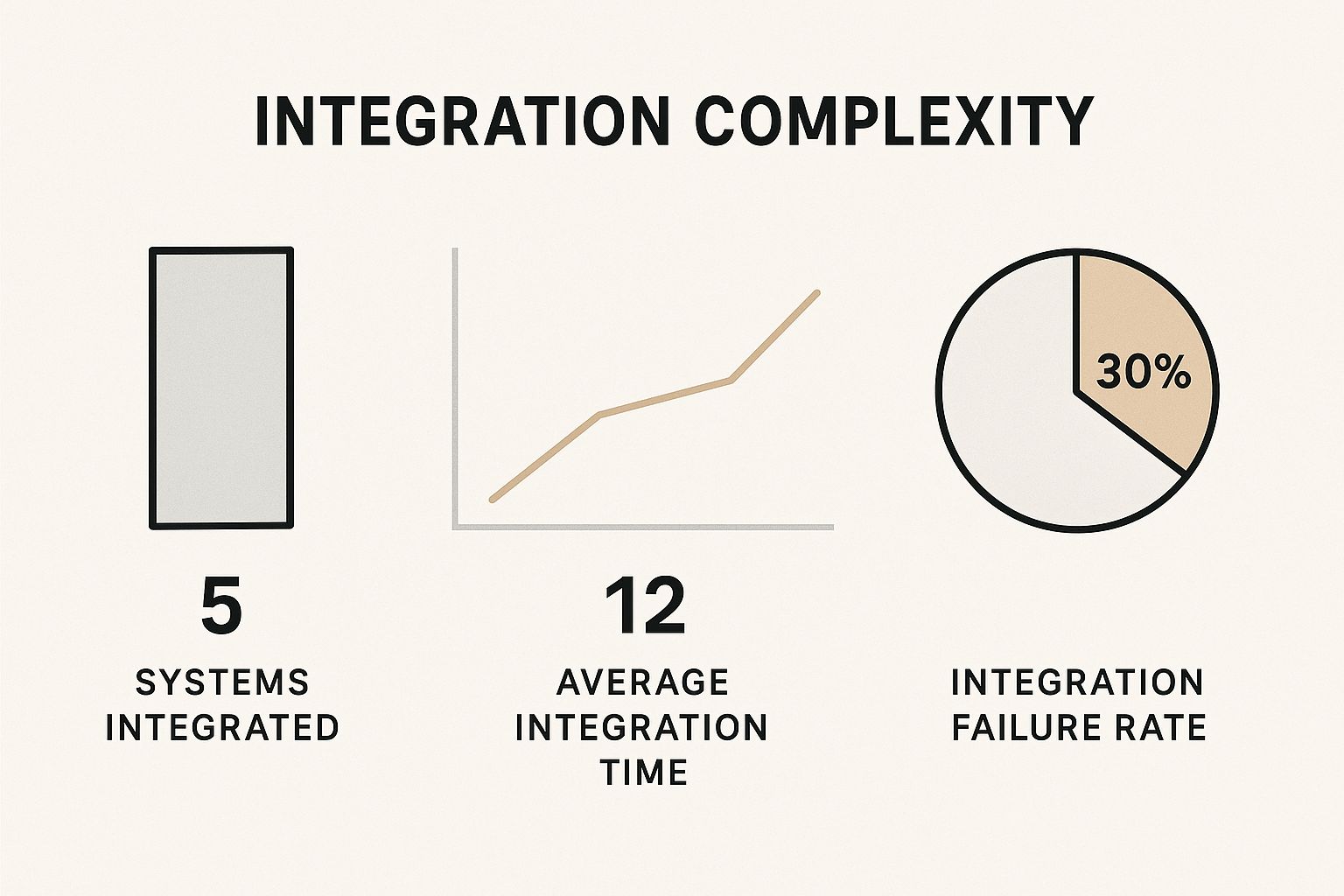

This infographic shows just how complicated system integrations can become, even in moderately complex projects.

The chart highlights that even a handful of system integrations can lead to significant delays and a surprisingly high failure rate, which makes realistic planning absolutely critical.

To help you sidestep these common errors, the table below breaks down the most frequent planning mistakes and their typical impact on a project's budget and schedule.

Table: Common Planning Mistakes and Their Impact

Analysis of frequent planning errors and their consequences on project outcomes

| Planning Mistake | Frequency | Average Cost Impact | Timeline Delay | Mitigation Strategy |

|---|---|---|---|---|

| Scope Creep | High | 15-25% over budget | 3-6 months | Create a detailed project charter with a clear scope; implement a strict change control process. |

| Over-Reliance on Vendor Demo | Moderate | 10-20% over budget | 2-4 months | Conduct independent, deep-dive workshops with the vendor using your company's real data and scenarios. |

| Inaccurate Timeline Estimates | High | 10-15% over budget | 4-8 months | Build in a 15-20% contingency buffer; involve the implementation team in creating the schedule. |

| Poor Requirements Gathering | Very High | 20-30% over budget | 6-9 months | Involve a cross-functional team from the start; document all processes and get departmental sign-off. |

As the data shows, these mistakes are not just inconvenient—they have serious financial and operational consequences. A clear plan is your best defense.

To avoid these pitfalls, a solid project management approach is non-negotiable. Here’s how you can build a more durable plan:

- Develop a detailed project charter: This document must clearly define the project's goals, scope, key players, and what success looks like. It acts as your guidepost to prevent scope creep.

- Bring in a cross-functional team early: Get insights from finance, HR, operations, and IT right from the beginning. Their firsthand knowledge is essential for identifying true needs and potential roadblocks.

- Build in a contingency buffer: A good plan is a realistic one. Assume things will go wrong and add a 15-20% buffer to both your budget and timeline to handle unexpected issues without derailing the project.

Technical Nightmares That Blindside Smart Organizations

Beyond strategic missteps and resistance from your team, there are purely technical ERP implementation issues that can stop a project in its tracks. These aren't just minor bugs; they are deep, structural problems that often catch even tech-savvy companies off guard. Think of your new ERP as a high-performance engine for your business. The technical hurdles are like trying to install this modern engine into an old car frame with mismatched parts—it’s far more complicated than just bolting it in.

What seem like straightforward tasks—such as data migration, system integration, and software customization—can quickly spiral into multi-year ordeals. These challenges require careful planning and a realistic understanding of the work involved.

The Treacherous Path of Data Migration

One of the most underestimated technical challenges is data migration. On paper, it looks simple: just move information from the old system to the new one. In reality, it’s more like translating an ancient library of books into a new language, where every book is written in a different dialect and filled with handwritten notes in the margins.

Data that appears clean in your legacy systems is often riddled with inconsistencies, duplicates, and outdated formats. According to numerous industry reports, a significant number of ERP projects face major delays specifically because of data quality problems. When this "dirty" data is moved into a pristine new ERP, it doesn't just transfer—it corrupts the entire system.

The new system, which is built on strict rules of logic and consistency, simply cannot function with flawed information. This triggers a cascade of errors: financial reports become inaccurate, customer orders get botched, and inventory counts are no longer reliable. The only fix is a painstaking, manual data cleansing process that can add months and significant costs to the project, all while the organization struggles to operate on shaky ground.

Customization and Integration Traps

Another major pitfall is the tempting call of customization. It’s common for teams to want the new ERP to work exactly like their old, familiar systems. This leads to requests for custom modifications, which might seem harmless at first. However, even a small tweak can create a complex web of dependencies that are difficult to manage.

Think of it like altering a single support beam in a building; you might not realize it, but you could be compromising the structural integrity of the entire floor above. A simple customization in the finance module, for instance, could unexpectedly break a critical function in your supply chain module.

This creates a dangerous form of technical debt. Each customization makes future system upgrades more difficult and expensive because every change must be re-tested and often rebuilt from scratch. Similarly, integrating the new ERP with other essential business applications—like a CRM or a specialized logistics platform—is rarely a simple plug-and-play task. Hidden incompatibilities in how these systems communicate can lead to silent data loss or synchronization failures, creating operational chaos for your teams and technical nightmares for your IT staff.

Navigating Vendor Relationships Without Losing Control

The success of your ERP implementation often hangs on the expertise of external partners—the software vendor and implementation consultants. But a critical challenge is that their primary goals may not perfectly align with your company's long-term interests. Managing these relationships is a delicate dance. You need their specialized skills, but you can't afford to give up control over your project's direction and future.

One of the most common ERP implementation issues is becoming too dependent on consultants. Think of them as a highly skilled construction crew hired to build your company's new operational headquarters. You absolutely need their ability to pour the foundation and raise the walls, but you must remain the architect. If you let the crew make all the design choices, you might end up with a building that’s easy for them to construct but doesn't actually fit how your company works. The best projects are built on a partnership with clear contracts and a serious commitment to knowledge transfer, not just a race to the finish line.

Structuring Partnerships for Success

The foundation of your vendor relationship is the contract. A vague or poorly structured agreement is a recipe for future conflict and budget overruns. Instead of accepting a generic statement of work, you should push for a contract that ties everyone's success together and clearly outlines who is responsible for what.

Here are a few key practices to help you stay in the driver's seat:

- Define Clear Deliverables and Milestones: Don't just pay for hours worked. Tie payments to the successful completion of specific, measurable project milestones. This simple shift creates a powerful incentive for your partners to deliver tangible results and stay on schedule.

- Insist on Knowledge Transfer: Your contract must state that consultants are required to train your internal team throughout the project. The ultimate goal is self-sufficiency. You want your own staff to be able to manage, maintain, and troubleshoot the system long after the consultants have moved on to their next project.

- Establish a Governance Framework: Create a steering committee that includes key members from your team and the vendor's team. This group should meet regularly to review progress, tackle roadblocks, and make important decisions together. This ensures you always have a voice and a clear view of the project's status.

Avoiding Consultant Dependency

It's easy to fall into the trap of over-relying on external experts. While their knowledge is essential at the start, the long-term goal is to build up your own team's capabilities. A major red flag is when a single consultant becomes the only person who knows how a critical part of the system works.

To prevent this "knowledge silo," make sure your employees are actively involved. Assign them to shadow consultants, document processes as they're being built, and eventually take full ownership of specific system modules. This approach ensures that the expertise you're paying for is absorbed into your organization, not just rented for a few months.

A strong partnership isn't just about getting a project done. It's about empowering your team for the future. By structuring your contracts with care and prioritizing the development of internal skills, you can ensure your new ERP system becomes a sustainable asset that grows with you, not a source of endless dependency on outside help.

Your Blueprint For ERP Implementation Success

Knowing what can go wrong is just one piece of the puzzle; the other is building a solid plan to get it right. After exploring the common ERP implementation issues, from employee pushback to technical glitches, it’s time to shift our focus from problems to solutions. This blueprint isn't a theoretical wish list. It’s a practical guide built from the hard-won lessons of organizations that have successfully navigated these challenges.

The first step is to move from hopeful assumptions to a structured, realistic plan. A recurring theme in failed projects is a fuzzy line of accountability. To prevent this, you must form a project steering committee with the real authority to make decisions. This group should be a mix of executive sponsors, department heads, and project managers who meet weekly to track progress against clear metrics. Their role isn't just to watch timelines; it's to actively remove obstacles, manage changes through a formal process, and keep the project tied to its original business goals.

Building Lasting Internal Capability

Relying entirely on external consultants for your ERP project is like hiring a chauffeur without learning to drive yourself. It works for a while, but you're left stranded when they leave. The real goal should be knowledge transfer. Your plan must include ways to build up your own team's expertise from the very beginning.

Have your key employees work side-by-side with the implementation partners, not just get occasional reports. Let them help document new processes, weigh in on configuration choices, and grow into the resident experts for their departments. This approach pays off long after the project ends, making sure your organization can manage, adapt, and improve the system on its own.

This chart from Gartner shows the modern ERP environment, highlighting the different strategic parts that need strong internal teams to manage them well.

The visual makes it clear that a modern ERP isn't one single piece of software but a collection of applications. It takes a skilled internal team to pull them all together and create a business advantage.

A Framework for Realistic Expectations and Success

Managing expectations requires a careful balance. You need to keep the team excited while also being honest about the challenges. A successful project isn't just about launching on time; it's about achieving real business improvements.

Use this framework to guide your project's decisions:

- Define Success Metrics Beyond Go-Live: Don't just track if you're on budget and on schedule. Measure things like user adoption rates, improvements in process speed (like faster order processing), and better data accuracy. These are the metrics that show real value.

- Establish a Change Control Board (CCB): This is a small group, usually part of the steering committee, that formally reviews every request for a change. Each request must come with a business case, an analysis of its impact on the budget and timeline, and a clear return on investment. This changes the question from "Can we add this feature?" to "Should we add this feature?"

- Implement Phased Rollouts: A "big bang" launch, where everything goes live at once, is incredibly risky. A phased approach lets you learn and adjust as you go. For instance, you could roll out the finance module first, make sure it's stable, and then tackle the supply chain module. You can even explore specific components, like a CRM, before the full system goes live. To get a better feel for this, you can check out our guide on how to use Odoo CRM to see how a modular approach can work.

By following this blueprint, you can turn a high-stakes ERP implementation into a well-managed, strategic project.

At KP Infotech, we guide businesses through these complex projects. We don't just install software; we build partnerships to ensure your ERP becomes a foundation for future growth. Contact us to start building your success story.